11

2025

-

07

Factory vs. Trading Company: What’s Better for Bulk Aluminium Window Orders?

Factory vs. Trading Company: What’s Better for Bulk Aluminium Window Orders?

When sourcing aluminium windows, doors, and cabinets in bulk, international buyers face a fundamental decision—should you work with a direct factory or go through a trading company?

This choice can significantly impact pricing, product customization, communication efficiency, and long-term cooperation. As developers, contractors, distributors, and project owners, understanding the pros and cons of each is critical to making the right call.

1. What Do B2B Buyers Really Want?

Bulk buyers are not just looking for a supplier—they seek:

Stable production capacity

Competitive factory pricing

Customization flexibility

Consistent quality control

Responsive communication

Long-term cooperation mindset

Only by partnering with the right type of supplier can these goals be achieved. So, which is the better choice?

2. Trading Company vs. Factory: Key Differences

Criteria | Trading Company | Direct Factory |

|---|---|---|

Pricing Transparency | Often adds 10%–30% markup on original costs; breakdown is unclear | Factory-direct pricing with transparent cost components like materials, processing, and labor |

Product Customization | Limited to standard models; complex customization must be relayed to the factory, causing delays | Fully customizable to drawings and project requirements — size, structure, glass, smart hardware, etc. |

Technical Support | Relies on third-party factories; responses may be slow or lack technical depth | In-house engineering and design team provides fast CAD drawings, structural advice, and feasibility evaluation |

Production Lead Time Control | No direct influence on production schedule; delays due to factory overload are common | Production is scheduled and monitored in-house; flexible lead time and batch delivery are available |

Quality Control & Traceability | No consistent QC system; quality issues are harder to trace and resolve | Full in-house QC at every stage: raw materials, semi-finished, final inspection — detailed reports available |

Project Experience | Mainly resells from different factories; lacks deep involvement in project execution | Experienced with large-scale projects (residential, hotels, offices), familiar with international standards |

After-sales Support | After-sales requests must go through layers; resolution time is often long | Dedicated account manager with fast response and access to technical files and spare parts |

Factory Audit Possibility | No manufacturing site to audit; not valuable for on-site inspection | Factory welcomes visits, virtual tours, or third-party audits to verify capacity and process flow |

Communication & Language Skills | Sales-focused communication; may lack technical clarity | English-speaking sales + technical team ensures smooth collaboration with overseas project teams |

Long-term Partnership Potential | Short-term order-driven model; trading partners may change frequently | Focused on long-term cooperation with flexible terms, framework agreements, and localized stocking plans |

Verdict: For large-scale, custom, or repeat projects, a factory usually provides better value and control.

3. How to Assess a Real Factory Before You Commit

If you decide to work directly with a factory, here’s how to verify and evaluate:

Request Business License + Export Certificate

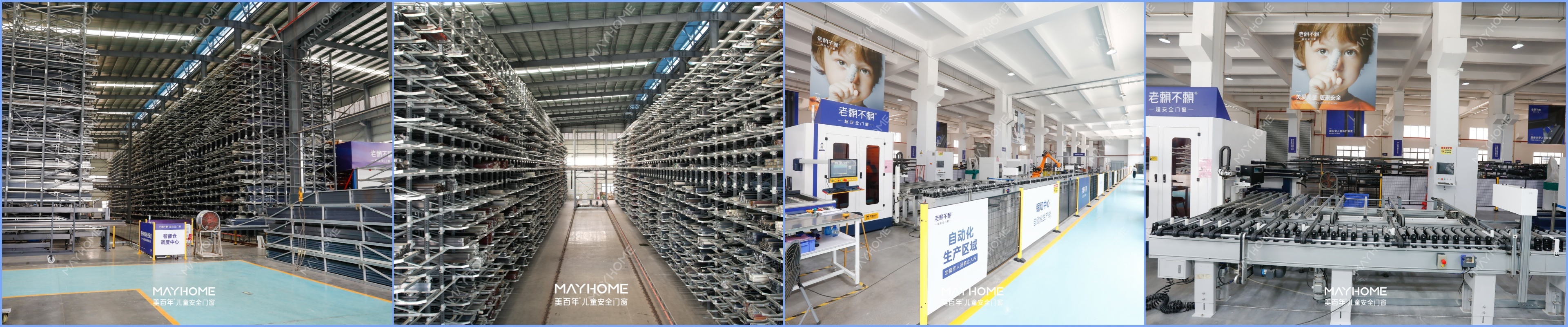

Ask for Factory Video Tour or VR Showroom Access

Check In-house Production Lines (cutting, extrusion, coating, assembling)

Review Past Projects / Case Studies

Understand QC Procedures & Certifications (e.g., ISO, CE)

Evaluate Communication & Technical Support Capabilities

A trustworthy factory will always welcome your audit, whether remote or on-site.

4. Online + Offline: A Strategic Path to Factory Engagement

We recommend a 3-step engagement path for overseas buyers:

Step 1: Online Verification

Use platforms (e.g., Made-in-China, Alibaba, company websites) to check registration details, product range, videos, certifications, and case studies.

Step 2: Live Communication

Schedule a video call, request a virtual tour, and ask specific technical and business questions. See how the team responds.

Step 3: Factory Visit or Third-party Audit

If possible, arrange a site visit or appoint a local inspection agency to verify operations, quality control, and factory capacity.

This approach reduces risk and builds a foundation for future collaboration.

5. Final Thoughts: Think Long-Term

Trading companies may offer short-term convenience, but for bulk orders of aluminium windows and cabinets—especially with custom needs—a direct factory ensures transparency, cost-efficiency, and reliability.

If you're looking to build a long-term supply chain, start by working with the right manufacturer from day one.

Ready to assess a real aluminum window and cabinet factory?

We invite B2B partners to explore our production site virtually or visit us in person. Discover how we turn architectural ideas into precision-crafted aluminum solutions.

👉 [Learn More about Our Factory]

👉 [Book a Virtual Tour / RFQ]

Keywords: Casement Window

Get a Free Quote

We welcome you for any inquiries,tell us about your project to receive a no-obligation price quote

Mob/Whatsapp/Wechat

Tel

Address

No.50-6. Area D, Sanshui Industrial Park, Leping Town, Sanshui District, Foshan City, Guangdong, P.R.China

Follow Us